Navrattan Holdings Ltd. Introduces Thermo Chemical Gasification In India

India has become one of the

fastest-growing economies in the world. The fast-paced growth of the economy

which is the 3rd largest in terms of GDP has resulted in a surging demand for

energy. The ever increasing demand for energy is projected to grow at a rate of

3% over the next two decades. The increase in demand for energy to cater to a

large population; we are inclined to develop and harness environmentally

friendly clean and ‘green’ energy resources in-line with the global trend.

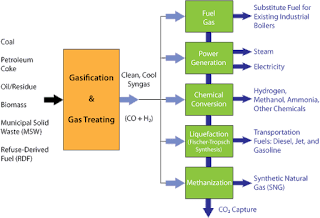

Navrattan Holdings Limited has

become the first company to introduce Navrattan Thermo Chemical Gasification

Technology in India. The revolutionary technology is capable of converting any

carbon-containing feedstock such as biomass, coke, sewage, agricultural,

animal, medical, and municipal solid waste into ‘Green’ electricity, natural

gas, and biofuel. The gas thus produced is called the ‘Syngas’. SYNGAS is a

shortened name for Synthetic Gas that commonly deals with the blend of hydrogen

and carbon monoxide. It is a clean, dry, flexible fuel.

THE BASICS OF GASIFICATION

Thermo Chemical Gasification (TCG)

is a process that involves various stages; pre-treatment of the feedstock, the

gasification processes itself, gas cleaning and the utilization of the gas.

The pre-treatment of the feedstock

is essential to achieve the high performance of the gasifier. During

the Gasification stage, the feedstock and gasification media like air, oxygen

steam or a mix of these are injected into the system. The gasification media

breaks down the feedstock. The efficiency is higher in gasification processes

as they can be run at a higher temperature than combustion. 70 - 80% of the

energy contained in the feedstock is converted to the energy content of the

Syngas, the rest being heat and losses.

The Synthetic Gas produced

primarily constitutes hydrogen (H) and carbon monoxide (CO). Cleaning the gas

is an important step especially the removal of tar particles as they can damage

the gas engine.

SOURCES OF SYNGAS

One of the many advantages of the

use of Synthetic Gas to produce clean fuel is that it can be produced from

waste materials which would otherwise, need to be discarded. Instead of placing

waste products in landfills or the oceans, this waste can be used to generate

useful and eco-friendly fuel. This makes the Thermo Chemical Gasification

process both an efficient means of producing energy and an environmentally

friendly option for the recycling of waste products.

Virtually any carbon-based material

can be gasified to produce syngas. The carbon that is stored in the plant

material is released as carbon monoxide and carbon dioxide allowing for nearly

all the carbon in the biomass to be converted to syngas.

ABOUT THE FOUNDER & CHAIRMAN OF NAVRATTAN GROUP

Mr. Himansh Verma, the Founder & Chairman of Navrattan Group plays a huge role in bringing this novel technology in India. Mr. Verma is a visionary who has researched and developed over 60 innovative technologies with the help of eminent scientists.

ADVANTAGES OF SYNGAS PRODUCED BY NAVRATTAN’S TCG TECHNOLOGY

Some of the major benefits of Syngas produced through Thermo Chemical Gasification is:

1. Generation of renewable power.

2. Conversion of waste materials to useful and ‘clean’ fuels.

3. Feedstock flexibility.

4. Low capital cost – less than ½ the cost of conventional designs.

5. Cost-effective and cleaner than conventional combustion process.

6. One of the most efficient technologies for waste treatment.

7. Rapid deployment – 12 months or less for a single unit.

8. Modular plant design.

9. Reduced carbon emissions.

Comments

Post a Comment